Customized Size 99.6% Pure Ti Pipe/Tube Gr1/Gr2/Gr5, Lightweight Durable, Automotive

- Product Details

Product Description

Exceptional Corrosion Resistance: This product boasts a corrosion resistance grade 5, making it ideal for applications where exposure to harsh environments is a concern, such as in coastal or chemical industries, as requested by a user in a specific industry.

High-Quality Material: The product is made from high-purity titanium (99.6% Ti content), ensuring exceptional strength and durability, particularly in applications like sporting goods and jewelry, such as glasses and earrings.

Versatile Applications: With a range of applications including industrial, sporting goods, glasses, and earrings, this product offers flexibility for various industries and uses, meeting the diverse needs of customers.

Customizable Processing Services: The product can be processed through various techniques, including drawing, bending, welding, decoiling, cutting, and punching, allowing for customization to meet specific user requirements.

Competitive Pricing: With a minimum order quantity of 1 kg and a competitive price per bar, this product offers an attractive option for businesses and individuals seeking high-quality titanium products at an affordable price, as required by users seeking a cost-effective solution.

Product Specification

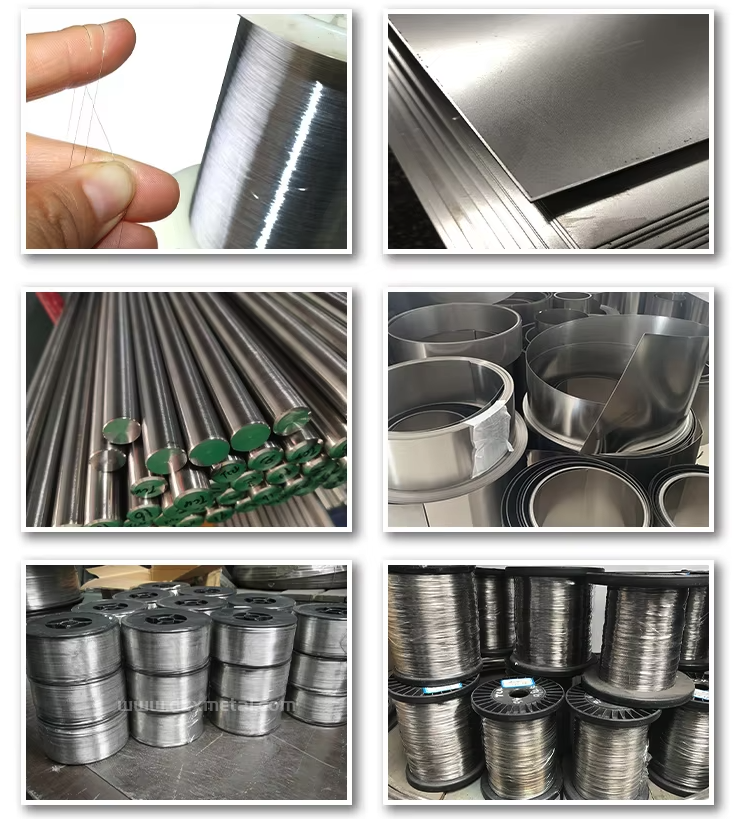

The main standard of Titanium Wire : GB/T3623-2007, ASTM B863, GBT 3620.2-2007

Titanium wire grades:TA1,TA2,TA3,TA4,TA5,TA6,TA7,TA9,TA10,TC1,TC2,TC3,TC4,TC6,TC11,GR1,GR2,GR3,GR5,Ti6AL4V ELI,Ti6AL7Nb,Ti13Nb13Zr,Ti1533

Titanium wire specification: φ0.8-φ6.0mm

Specs of titanium wire for glasses: special titanium wire for φ1.0-φ6.0mm

Titanium wire specifications: φ0.2-φ8.0mm special for hangers.

Supply Status of Titanium Wire: Annealed state (M), Hot working state (R), Cold working state (Y) (annealed, ultrasonic flaw detection)

Surface treatment of titanium wire: Pickled Surface Bright, Surface

Titanium wire "inherits" the advantages of titanium and titanium alloys, and has a series of excellent characteristics such as good corrosion resistance, high specific strength, non-magnetic, high biocompatibility, low resistance to ultrasonic waves, and good shape memory function. Therefore, titanium and titanium alloy wires are widely used in automotive, construction, sports and leisure products, and many other fields. And in recent years, due to its continuous development, the variety has become more and more diverse, which provides more choices in high-performance industrial and consumer applications.

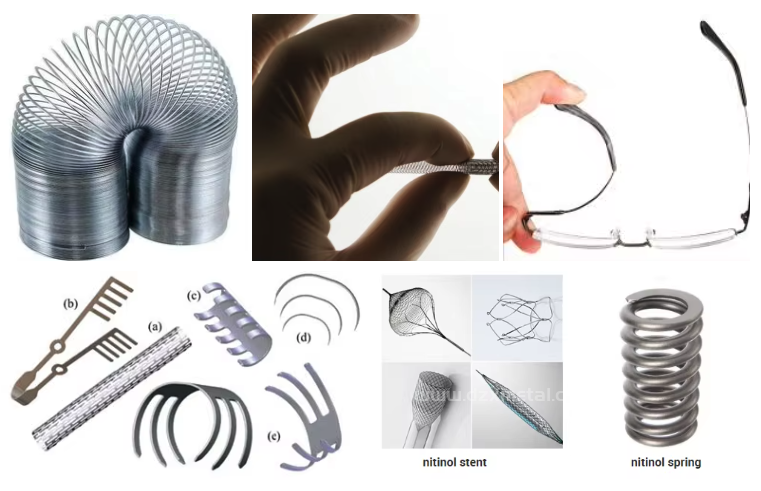

1. At present, more than 80% of titanium and titanium alloy wires are used as welding wires, such as welding of various titanium equipment, welding of pipes, and welding of casings. 2. Due to its excellent corrosion resistance, titanium wire has been widely used in chemical, pharmaceutical, papermaking, and other industries, and can be woven into a mesh as a seawater filter, pure water filter, chemical filter, etc. 3. Titanium and titanium alloy wires are also used to manufacture fasteners, load-bearing components, springs, etc., due to their good comprehensive properties. 4. In the health industry, due to its excellent biocompatibility, titanium and titanium alloy wires are used to manufacture implanted dental crowns and skull fixation. 5. Certain titanium alloy wires with shape memory function, such as titanium-nickel alloy wires, shoulder pads for clothes, women's bras, glasses frames, etc.

6. In the electroplating and water treatment industries, titanium and titanium alloy wires are used to manufacture various electrode

Production Applications

Sporting goods, glasses, earrings, headwear, electroplating hangers, welding wire, and other industries.

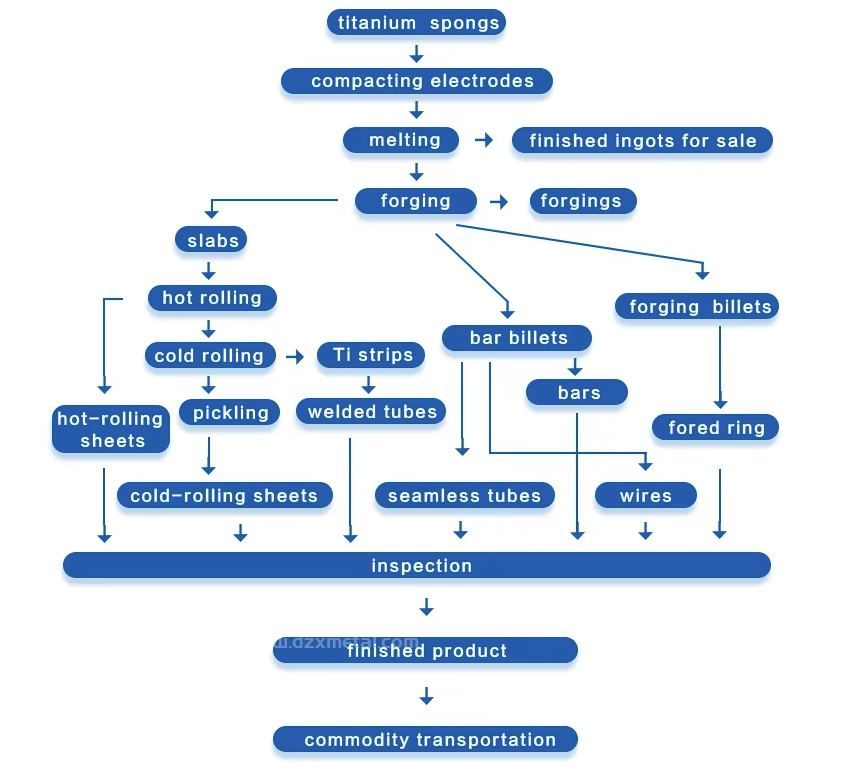

Production Process

Product Details

Product Equipment

Company Profile

Certification

Why Choose US?

Packing & Shipping

FAQ

What is your working time and contact information?

Monday-Saturday: 7:30 AM-5:00 PM (Beijing time, GMT+08.00)

We have a public holiday in May.1-3, Oct.1-7, and the Chinese New Year holiday.

Pls email us during our holiday if you have any questions.

How can we get in touch with you?

Mobile/WhatsApp/WeChat/Skype: +8619906119641

E-mail: sales8@dlx-alloy.com

Contact: Lawrence

Do you provide free samples?

Yes, we can provide a free sample for testing; the buyer should bear all the shipping costs.

What are your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.